The role and benefits of iron powder for oxygen absorbers

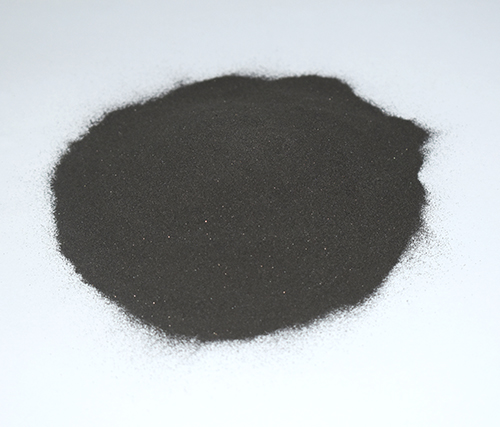

There are many types of oxygen absorbers that can cover a wide range of applications. Oxygen absorbers are usually a mixture of iron powder, sodium salt (common salt) and activated carbon (charcoal) powder; iron powder is the main component, and sodium salt acts as an activator, causing iron The particles rust, and if used properly, the pre-alloyed iron powder effectively reduces the oxygen level in the surrounding atmosphere to about 0.01%. Activated carbon acts as a gas absorbent and catalyst, and pre-alloyed iron powder further preserves the product and removes offensive odors. Although oxygen absorbers are not edible, they are not toxic. It does not generate harmful gases and does not eliminate the fresh smell and taste of the product.

According to food industry standards, when used as directed, the oxygen absorber pack removes oxygen from the sealed container to below 0.01%. When exposed to air, the iron in the package immediately absorbs oxygen and breaks it down into harmless iron oxide, which is safely contained in the package and does not contaminate food.

What are the benefits of using an oxygen absorber?

Extend shelf life; prevent the growth of aerobic pathogens and spoilage organisms (including molds); eliminate the need for additives such as BHA, BHT, sulfur dioxide, sorbate, benzoate; significantly improve the preservation of polyunsaturated fats and oils Quality; helps preserve fresh roasted flavors of coffee and nuts; prevents oxidation of spice oleoresins present in the flavors and flavored foods; prevents oxidation of vitamins A, C, and E; extends the life of medicines; flushes with gas / vacuum The packaging is used together to absorb almost all oxygen and any oxygen that may penetrate the packaging.